To better accommodate the diverse needs of our customers we also offer electroless nickel plating. Electroless plating has long been known for characteristics such as uniform application, its lubriciousness, solderability, and high resistant to corrosion. In most application these features would be enough, however at BHC Industries Plating; we're continually looking for ways to improve our processes. That's why we use AutoTech Heath 25 hard chrome plating in all of our plating tanks. This enhanced capability allows for even greater corrosion resistance, making it an ideal choice for components that are exposed to highly acidic environments. It's also harder than conventional chrome plating and leaves a finish that can achieve a Rockwell hardness of 38 to 42. Our 24' tanks can accommodate parts up to 12,000 lbs., and produce a plating of .0005" in thickness.

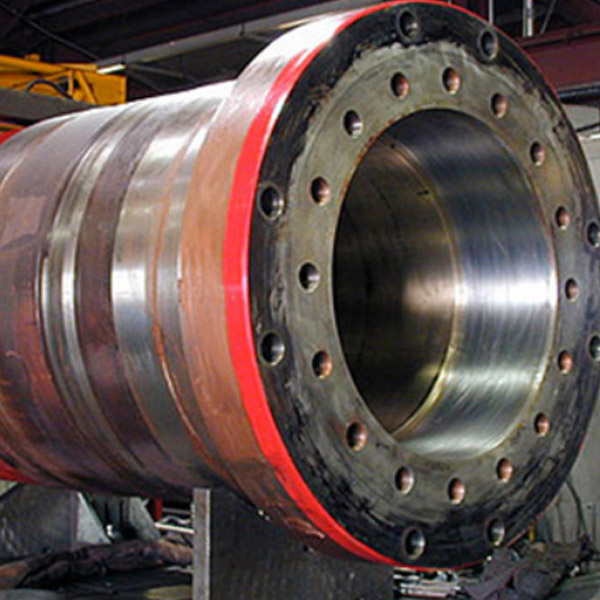

The products highlighted here, valve blocks used on a drilling rigs, and jack screws for an aerospace application, are an example of the wide range of metals that our plating can be applied too. 4140 steel, all ferris and non-ferris metals as well as proprietary materials can all benefit from our advanced plating capabilities.

To learn more about our plating services contact us directly.